Cogeneration

Presentation

We are working together with our partners from Belgium and UK in order to provide you complete cogeneration solutions CHP.Cogeneration (CHP) is the process of simultaneous generation of heat and power. The power derives from an internal combustion engine and is used to drive an alternator which in turn generates electric current. The dissipated heat is not lost but usefully applied for hot water production.

Today – but also tomorrow – Cogeneration is the green and sustainable solution for decentralized power generation.

Our engineers with work together with you to identify the best CHP solution.

You will find in us:

- Periodic maintenance

- Corrective maintenance

- Long-distance monitoring

- 2011 – 2 * 500 kw CHP units in Timisoara

- 2014 – 1 * 180 kw CHP at Râmnicu Sărat

- 2014 – Main sponsor for “Biogaz & Cogeneration National Conference

- 2017 – 2 * 810kw at Braila

- 2017 – 2 * 160kw at Braila

- Future development: 4 more units in Timisoara.

About cogeneration CHP

Cogeneration combined heat and power (CHP) is the use of a heat engine or power station to generate electricity and useful heat at the same time.

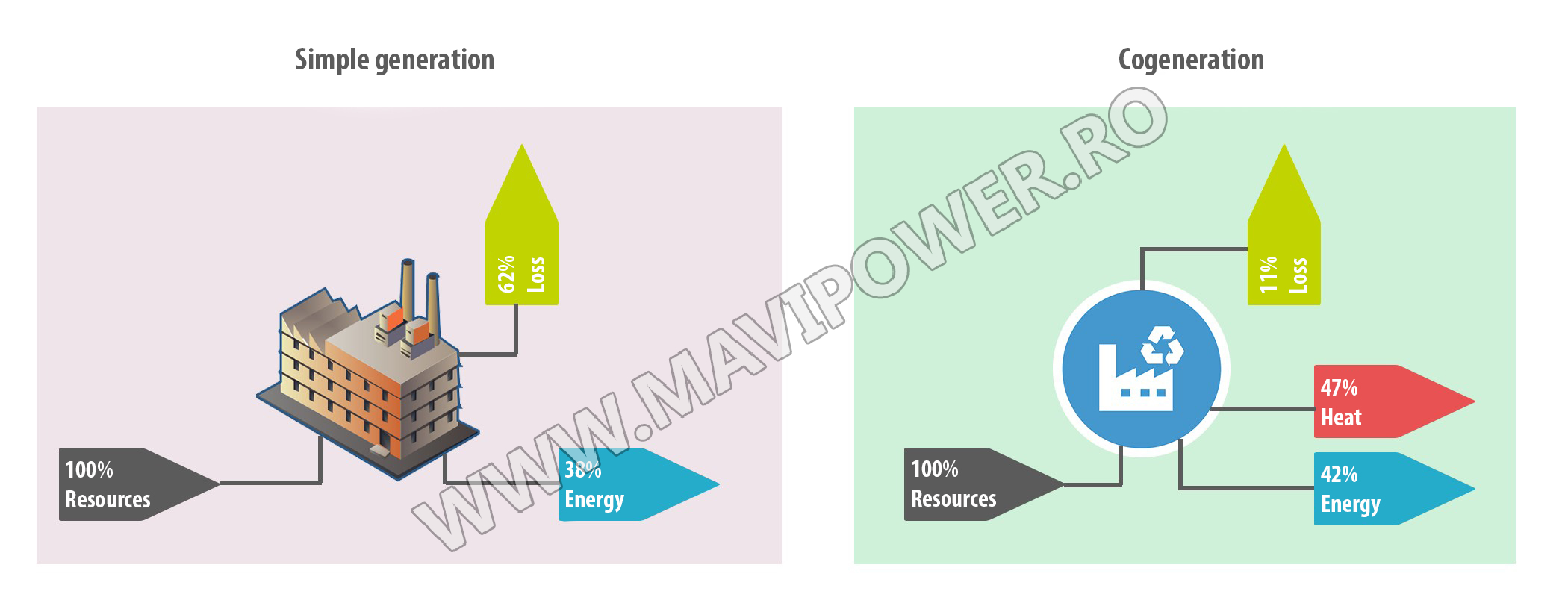

Energy is a precious yet a consumer of natural resources of our planet needed in order to provide the resources for our daily needs. Cogeneration involves an efficient usage of fuel (close to 90%). A cogeneration unit can assure around 25-40% operational savings with a 36-50 months amortization.

Because of its savings but also due to the low impact on the planet, Today the most efficient way for energy and power generation is actually cogeneration.

In most of EU countries cogeneration is considered one of the most effective and efficient tool in achieving the 3 objectives UE has for 2020:

- CO2 emissions reduction with 20%,

- 20% target for Renewable energy,

- Energy savings with 20%.

Cogeneration principle

Cogeneration or CHP means the simultaneous production of electricity and heat from the same primary source in the same process using the same fuel for two different uses, so the yield is much higher and the primary energy is used more efficiently.

Because significant cost savings can be made, cogeneration is used in many areas, from powering alternators to producing electricity, producing hot or steam water, producing simultaneous heat and cold for trigeneration.

A typical CHP unit contains:

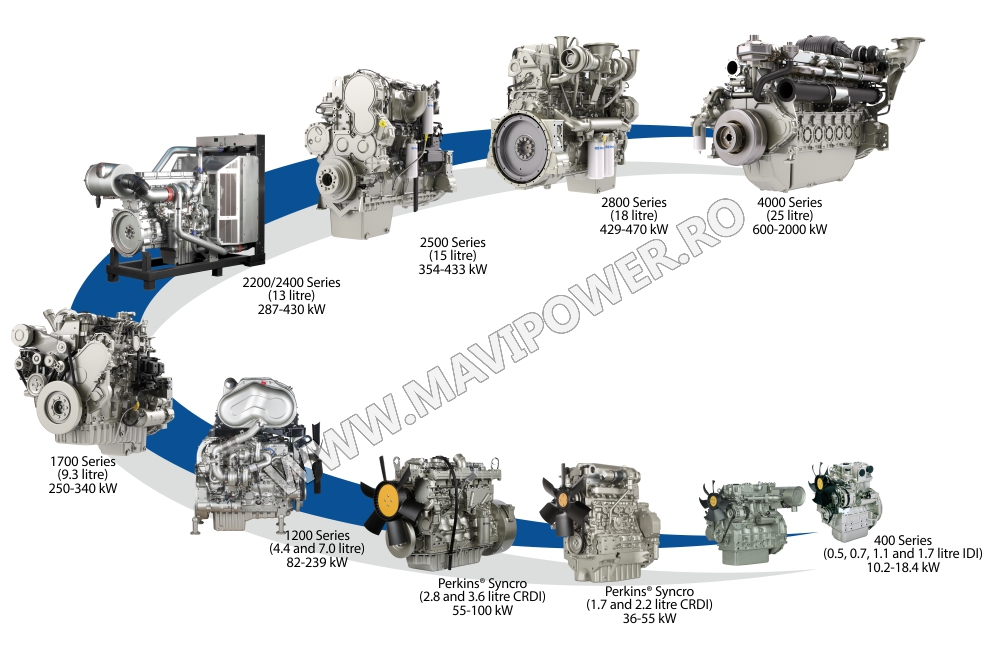

- Generator units (diesel or gas)

- Remote or on-side monitoring

- Pipes

- Heat recovery module, which includes:

- plate heat exchanger for the engine water jacket,

- exhaust gas heat exchanger

- cntrol panel for monitoring and protecting the system .

Photo Gallery

Folder Gallery Error: No picture available inside wp-content/uploads.