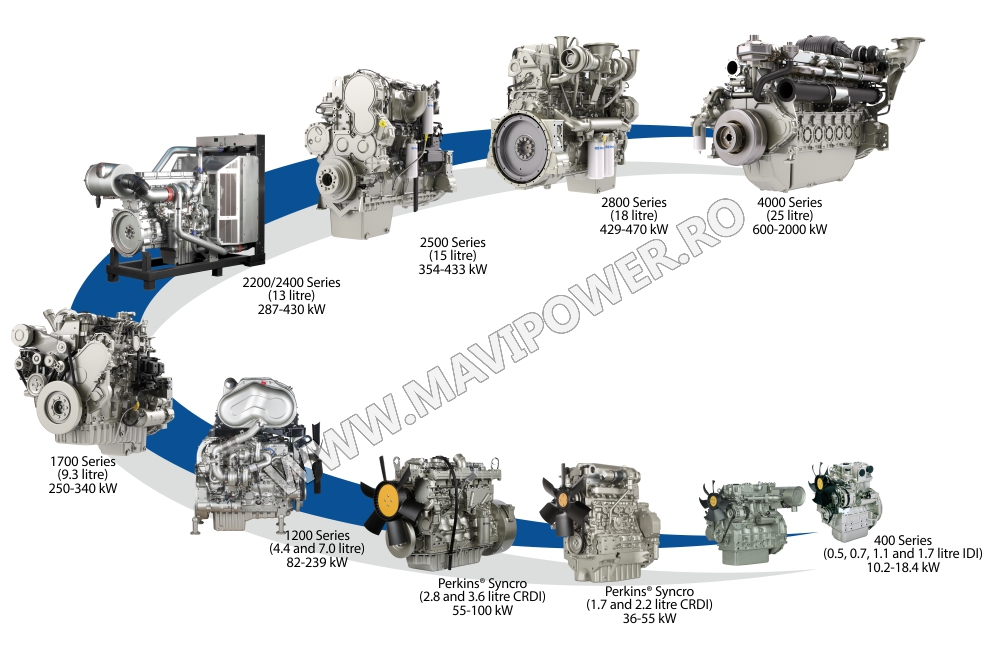

1200 Series

Presentation

SpecificationsOur 1200 Series engines offer a smart and clever solution for customers. The 4 and 6 cylinder models are with single and twin turbochargers and air intercooler. The choice of options, engine configurations and robust technology allows you to integrate the 1204 range into your equipment with minimum re-engineering. The innovative, compact and flexible design of the Perkins 1200 Series means it can be found in more than 800 different models of equipment.

Ideally suited to large and medium-sized machines.

Benefits & Features

A lifetime of low costs Perkins has designed the 1200 Series with optimized fuel consumption in mind, matching it to the operating cycles of a wide range of equipment and applications.

Low cost maintenance is achieved through hydraulic tappets, multi v-belts, after-treatment free service and 500 hour oil change intervals.

In addition, on the 1204F industrial engine, many service items can be located on either side of the engine to give you maximum access for servicing.

Easy to switch

The 1200 Series features core technologies and more options for changing of specification, to support your move from less emission to the latest emission standards. The technology consistently delivers with the minimum amount of difficulty.

Outstanding performance

Like you, we believe there is no need for a trade-off between meeting emission standards and delivering on performance. The 1200 Series tackles the emissions challenge head-on and gives you improved productivity levels and fuel consumption.

The powerful 1206 range outperforms the competition with its improved torque of up to 1282 Nm and outstanding transient response, making it the perfect choice for customers looking for reliable power. The 1206 range is an ideal solution for installation on large and medium equipment.

Ideal for downsizing

High power density, combined with excellent torque in the 1200 Series allows you to select a more compact engine where previously you might have used an engine of a higher cubic capacity. This downsizing has several benefits, including saving you money and providing more space to package the after-treatment units.

Tailored for your machines

Your needs are our top priority, which is why we provide more tailored technology for OEMs than anyone else. Working closely with OEMs, we have developed the 1200 Series with hundreds of variables so that it easily fits into your machine.

Our 1200 Series engines come with a two year warranties as standard and can also be supported by extended service contracts.

Tehnical details

| Model | Power (kWm) | Autonomy (he) | Power (kVA) | Emissions | Specifications sheets |

|---|---|---|---|---|---|

| 1206F-E70TTAG | 151 -223 | 135 – 200 | 169 – 250 | EU Stage IV/US EPA Tier 4 Final | Data sheet |

Technical specification:

- Aftertreatment technology

- 3ʺ flex pipe connection kit with rotatable elbow for 60° and 90° RS inlet flexibility

- DOC – Diesel Oxidation Catalyst

- DPF – Diesel Particulate Filter

- SCR – Selective Catalytic Reduction

- Air inlet system

- Standard air cleaners

- Control system

- Flexible and configurable software features and well-supported SAE J1939 CAN bus enables highly integrated machines

- Full electronic control system, all connectors and wiring looms waterproof and designed to withstand harsh off-highway environments

- Cooling system

- 50:50 water glycol mix

- Detailed guidance on cooling system design and validation available to ensure machine reliability

- Top tank temperature 108°C (226°F) as standard to minimize cooling pack size

- Flywheels and flywheel housing

- Wide choice of drivetrain interfaces, SAE No. 1, SAE No. 2 and SAE No. 3 configurations

- Fuel system

- Electronic high pressure common rail

- Inovative air filter design for maximum protection of the engine

- General

- Available with or without balance unit

- Cold start capability

- Engine mounts

- Oil system

- Choice of sumps for different applications

- Oil filters and carter gases closed circuit

- Standard emissions control equipment

- NRS – NOx Reduction System